The global fibre reinforced (carbon, glass, aramid and natural) composites market size was valued at 113.7$ billion in 2022 and is projected to reach 168.6$ billion by 2027, growing annually at 8.2% from 2020 to 2027 [1]. The largest market players currently originate from the aerospace, wind energy, construction, and automotive [2] sector. The main advantage of these composite materials are their low weight and high mechanical properties, which enables e.g., reduced fuel consumption and the associated reduction in CO2 emissions [3].

Wind energy market is also using composites to increase the length of the turbine blades to improve the efficiency in the generation of power [4]. According to WindEurope at least 14.000 wind turbine blades (WTB) will be decommissioned in Europe by 2023 for recycling, and more than 350.000 t of decommissioned blades will be by 2030 [5]. Nowadays, End of life (EoL) WTB management is based on

- Repurposing of ‘ok blades’ in secondary wind farms

- Landfilling, around 60% (most of them are buried)

- Grinding and burning in cement factories for energy recovery (downcycling)

- Repurpose EoL blades as art/urban furniture (minor trend in Denmark) [6]

Circularity of WTB is basically close to zero today.

Taking into account that landfill of composites has started to be forbidden in some European countries (such as Germany, Austria, Finland, and the Netherlands) and the fact that the European Commission seeks to reduce the amount of waste that can go to landfill to 10% by 2030 it is urgent to increase the amount of composites waste that is recycled to reduce primary energy demand and global warming. On a global scale, an estimated 2.5 Mio t of composite materials are currently in use in wind turbines, but cost-efficient recycling of composite materials remains a challenge [7].

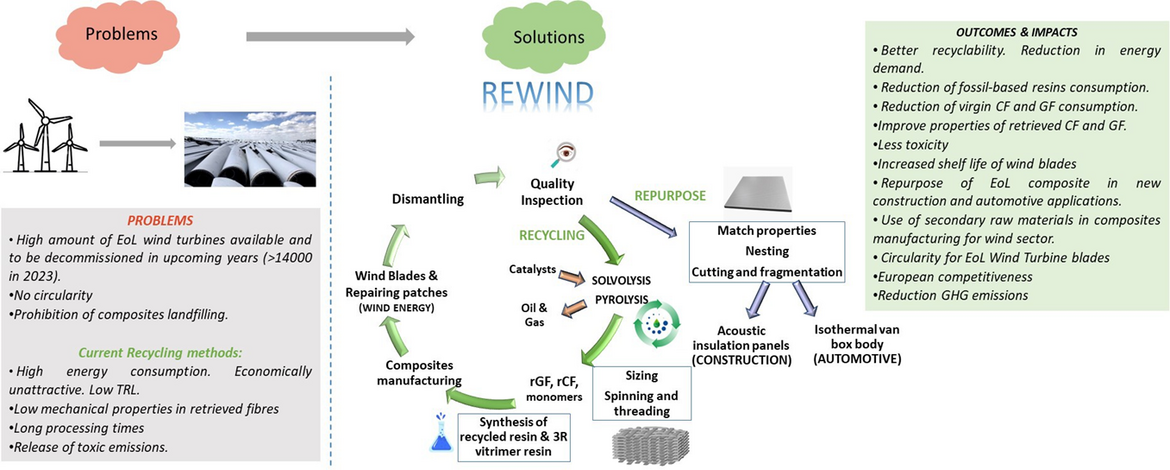

In this context, REWIND aims at developing critical technologies for dismantling end-of-life (EoL) wind turbine blades (evaluation, advanced cutting, etc.) and implementing new methodologies for composites repurposing and recycling (catalytic pyrolysis and solvolysis) to increase the circularity of WTB, as shown in Figure 1, increasing the industrial applications of the EoL composites, and avoiding the current landfilling or incineration. The main composition of the composite waste is expected to be epoxy resin/carbon fibre (CF), epoxy resin/glass fibre (GF) and polyester resin/GF. The new methodologies will address the following challenges:

Study and development of suitable disassembly, quality inspection and characterisation of the composite waste, to be able to understand composite waste properties. As a result, it will be possible to decide if composite parts from EoL products should be repurposed or recycled depending on their value.

Repurposing will be demonstrated through manufacturing two demonstrators (for construction and automotive sector). This will be done by matching specified requirements with dismantled materials using software and hardware tools to facilitate the fragmentation processes (both sectors are very large contributors to the global CO2 emissions continuously searching for circular materials and trying to maximise the recyclability of the materials used).

New innovative pyrolysis and solvolysis methods for recycling will be developed and tested to significantly reduce the processing temperature and time for those parts that cannot be used in repurposing. This will allow to save energy, and together with the post-treatments, improving the quality of the materials recovered (e.g., weaved fibres, sized fibres, recycled polyester resin, recycled epoxy resin and epoxy vitrimer resins based on recycled monomers). Secondary raw materials obtained will be used to manufacture two demonstrators for wind energy sector: a small wind blade root section and composites patches for blades repairing. REWIND technologies will be scalable to process high volumes of waste in the near future.

- Asociación Investigación Materiales Plásticos y Conexas AIMPLAS

- Fundación Tekniker

- Centre Technique Industriel de la Plasturgie et des Composites

- MILJOSKARM APS

- Hochschule Pforzheim

- Deutsche Institute fur Textil-und Faserforschung Denkendorf

- ALKE SRL

- National Technical University of Athens

- Suez Group

- BCIRCULAR COMPOSITES, S.L.

- Composite Patch

- TPI Composites

- Ciaotech SRL

- Asociación AEMAC

The project REWIND is funded by Europeans Union´s Horizon Europe Framework Programme (HORIZON) under grant agreement No 101147226

Duration 01.05.2024 - 30.04.2028